Metropolitan® M-94

Metropolitan® M-94

The METROPOLITAN M-94 is designed around the needs of the people who maintain and repair it. That’s why we’ve kept the number of parts to a minimum and designed the hydrant so it is easily repairable by one person.

Features & Benefits:

- Made to comply with the requirements of ANSI/AWWA C502, UL 246, FM 1510, and made in a U.S. ISO9001 certified factory.

- A Ductile Iron bonnet is securely fastened to the upper standpipe with inter-locking “breech lock” lugs for tamper resistance. It is easily removed for access to the main valve.

- The bonnet locking screw is tamper resistant, assuring security of the bonnet by preventing its rotation.

- The Ductile Iron operating nut with a weather shield weatherproofs the hydrant. Ductile Iron provides durability and wear resistance. A tamper resistant alloy steel locking pin fastens the operating nut to the revolving nut.

- The bronze hold down nut is totally enclosed by the skirt of the weather shield and is locked in the bonnet for extra security. It is O-ring sealed for added protection.

- A stop nut provides a positive halt to movement of the valve rod while opening. The rod cannot be placed in compression if the hydrant is “over-opened.”

- An anti-friction bearing ensures easy operation by reducing friction. It is made of tough, reliable Acetal Polymer for strength and wear resistance.

- A lubrication chamber is filled with all-temperature grease ensuring positive lubrication each time the hydrant is opened.

- The revolving nut has three channels to allow the grease to move around the rod threads as well as above and below the thrust collar during operation.

- The bronze revolving nut is the direct connection between the operating nut and the rod threads. True dry-top design is double O-ring sealed.

- A bronze rod sheath provides a smooth bronze-to-bronze non-corrodible sealing surface for reliable, positive sealing by O-rings.

- The Ductile Iron upper standpipe resists traffic impact damage.

- The hydrant has streamlined curves. Both the nozzle section and the nozzles have sweeping curves to provide maximum flow and minimum head loss.

- The threaded-in nozzles are O-ring sealed and mechanically secured with stainless steel nozzle locks.

- PROTECTOP™ ground line coupling ensures reliable fracture and quick repair after traffic impact. The coupling can be easily removed to install an extension section or loosened to rotate the hydrant to any position after installation.

- The cast iron rod coupling is designed to break with traffic impact, leaving no loose pieces that could drop into the main valve area.

- The upper valve plate is all bronze construction with specially formulated rubber drain valve facings.

- The hydrant has a bronze drain outlet. To ensure a non-clogging drain way which leads to double drains in the sides of the shoe. Drains are forced flushed during opening and closing of the main valve.

- The compression main valve opens against pressure.

- The Ductile Iron shoe is epoxy coated on both the interior and exterior surfaces for maximum corrosion protection.

Maintenance Manual Brochure Full Line Catalog

Resources:

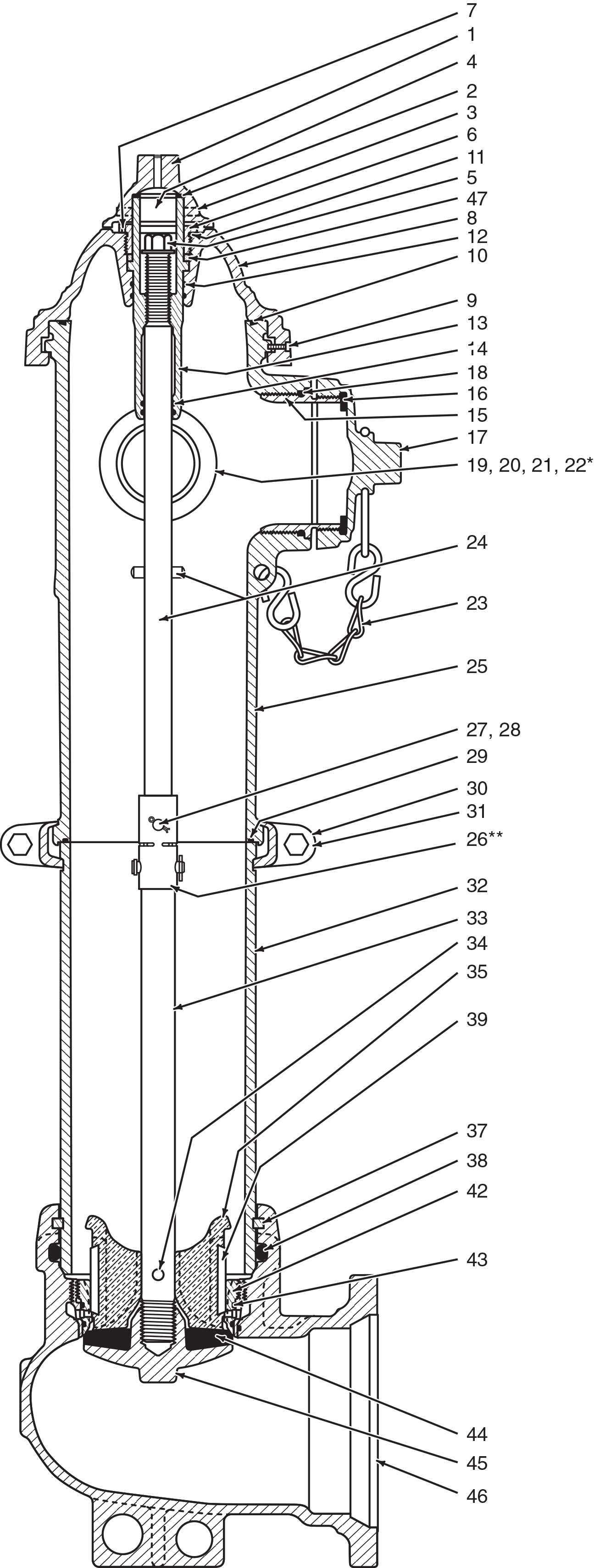

Item # | Part Name | Qty, | Material |

1 | Operating Nut with Lubrication Port | 1 | Ductile Iron |

2 | Operating Nut Seal | 1 | Rubber |

3 | Operating Nut Locking Pin | 1 | Steel |

4 | Hydrant Lubricant (in chamber) | 1 | Diana 2100 |

5 | Travel Stop Nut | 1 | Steel |

6 | Hold Down Nut | 1 | Bronze |

7 | Hold Down Nut Screw | 1 | Steel |

8 | Bonnet | 1 | Ductile Iron |

9 | Bonnet Locking Screw | 1 | Stainless Steel |

10 | Bonnet Seal | 1 | Rubber |

11 | Hold Down Nut O-ring | 1 | Rubber |

12 | Bonnet - Revolving Nut O-rings | 2 | Rubber |

13 | Revolving Nut | 1 | Bronze |

14 | Inner Revolving Nut O-rings | 2 | Rubber |

15 | Pumper Nozzle | 1 | Bronze |

16 | Pumper Nozzle Cap Gasket | 1 | Rubber |

17 | Pumper Nozzle Cap | 1 | Cast Iron |

18 | Pumper Nozzle O-ring | 1 | Rubber |

19 | Hose Nozzle† | 2 | Bronze |

20 | Hose Nozzle Cap Gasket | 2 | Rubber |

21 | Hose Nozzle Cap | 2 | Cast Iron |

22 | Hose Nozzle O-ring | 2 | Rubber |

23 | Chain Assembly | 1 | Steel |

24 | Valve Rod Upper, Including Copper Sheath with O-ring and Shear Proof Rod Pin | 1 | Steel |

25 | Standpipe Upper | 1 | Ductile Iron |

26 | Valve Rod Coupling (Frangible) | 1 | Gray Iron |

27 | Coupling Retaining Rings | 2 | Stainless Steel |

28 | Rod Coupling Pins | 2 | Stainless Steel |

29 | Standpipe Coupling Seal | 1 | Rubber |

30 | Standpipe Coupling Halves (Frangible) | 2 | Gray Iron |

31 | Standpipe Coupling Bolt and Nut | 2 | Stainless Steel |

32 | Standpipe Lower | 1 | Ductile Iron |

33 | Valve Rod Lower | 1 | Steel |

34 | Top Plate Pin - Shear Proof | 1 | Steel |

35 | Valve Top Plate | 1 | Bronze |

37 | Shoe Locking Key | 4 | Stainless Steel |

38 | O-ring Gasket | 1 | Rubber |

39 | Drain Valve Facing | 2 | Rubber |

42 | Seat Ring | 1 | Bronze |

43 | Seat Ring O-ring | 2 | Rubber |

44 | Main Valve | 1 | Rubber |

45 | Valve Bottom Plate | 1 | Ductile Iron |

46 | Shoe, Including Bronze Sub-Seat | 1 | Ductile Iron |

47 | Anti-Friction Bearing | 1 | Acetal |

*Not shown | Nozzle Wedge Lock | 3 | Bronze |

** Not shown | Dampener | 1 | Rubber |